BLOGS

Why Choose High Frequency Wood Board Joining Machines Over Traditional Wood Clamp Machines?

In the woodworking industry, panel joining is a critical process for producing wide boards, furniture panels, and other wooden structures. Traditionally, woodworking factories have relied on mechanical wood clamp machines to join boards together. However, as production demand and quality standards rise, many businesses are turning to high frequency (HF) wood board joining machines as a smarter, more efficient alternative.

In this article, we compare traditional wood clamp machines with high frequency wood board joining machines and explain why more manufacturers are choosing HF technology for modern wood panel production.

What Is a Wood Clamp Machine?

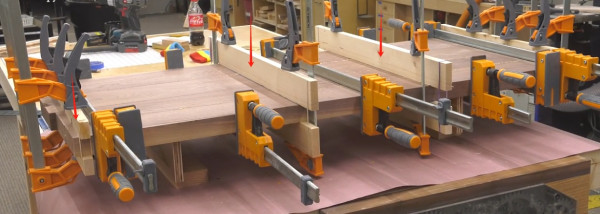

A wood clamp machine, also known as a mechanical clamp carrier, uses physical pressure and time to glue multiple boards together into a panel. The boards are manually loaded, glue is applied, and then the system applies pressure—usually for 30 minutes to several hours—while the adhesive cures naturally or with heat. It’s a traditional method that has been used for decades.

Limitations of wood clamp machines:

Slow curing time: Panels must stay clamped for a long time until the glue fully dries.

Labor intensive: Operators must load, align, and monitor the boards manually.

Large space requirement: The machines occupy a lot of floor space for clamping and curing.

Higher defect risk: Uneven pressure or poor alignment can result in gaps or weak joints.

What Is a High Frequency Wood Board Joining Machine?

A high frequency (HF) board joining machine uses electromagnetic waves to instantly heat the glue line between boards, curing the glue. The process is rapid, uniform, and automated. Within seconds to minutes, boards are tightly joined into panels with strong, consistent bonds.

Advantages of HF wood board joining machines:

1. High Efficiency and Short Curing Time

Unlike clamp machines that require long clamping periods, HF wooden board joining machines cure the glue in seconds. This significantly increases daily output and shortens production cycles—ideal for high-volume manufacturing.

2. Labor Saving and Automation

HF wood panel joining machines can be equipped with automatic feeding and pressing systems, which means fewer workers are needed. One operator can manage an entire line, reducing labor costs and increasing safety.

3. Strong and Uniform Bonds

High frequency energy penetrates the glue line and heats it uniformly, resulting in stable joints with better strength. The risk of unbonded areas or weak seams is drastically reduced.

4. Space Saving Design

Compared to clamp carriers, RF wood panel joining machines require less factory space. The compact structure and fast cycle times eliminate the need for large clamping areas.

5. Adaptability to Different Glues and Wood Types

HF wooden board joining systems are compatible with many industrial adhesives and various hardwoods and softwoods. This makes them suitable for a wide range of applications, including furniture panels, doors, flooring, and more.

Which Is Better for Your Factory?

If you are running a traditional workshop with small output, a clamp machine might seem like a cost-effective solution. But for modern woodworking factories, efficiency, precision, and automation are the key to profitability. In that case, investing in a high frequency board joining machine offers:

* Faster ROI through higher productivity

* Lower labor requirements

* Better product consistency

* Increased competitiveness in the market

Conclusion

As the woodworking industry continues to evolve, traditional equipment like wood clamp machines can no longer meet the demands of large-scale, high-precision production. High frequency wood board joining machines represent the next generation of panel manufacturing—faster, smarter, and more reliable.

Let your woodwork move faster—with high frequency technology.

Other News

Discover JYC High Frequency Woodworking Technology at Shanghai International Exhibition 2025

timer :

2025-08-19

China's Heading Wood Drying Solution: The Standard Setting HF Vacuum Dryer from JYC

timer :

2025-08-26