BLOGS

China's Heading Wood Drying Solution: The Standard Setting HF Vacuum Dryer from JYC

In industrial wood processing, the drying phase represents a critical determinant of product quality, energy efficiency, and environmental impact. JYC’s High Frequency Vacuum Wood Drying Machine embodies a sophisticated integration of electromagnetic energy application and vacuum chamber technology, delivering unmatched performance, sustainability, and operational autonomy.

Superior Drying Mechanism Through High Frequency Energy

High frequency (HF) drying operates on the principle of dielectric heating, wherein polar molecules within the wood—primarily water—are agitated by rapidly alternating electromagnetic fields. This generates internal heat uniformly throughout the material, substantially reducing conventional conductive and convective thermal resistances.

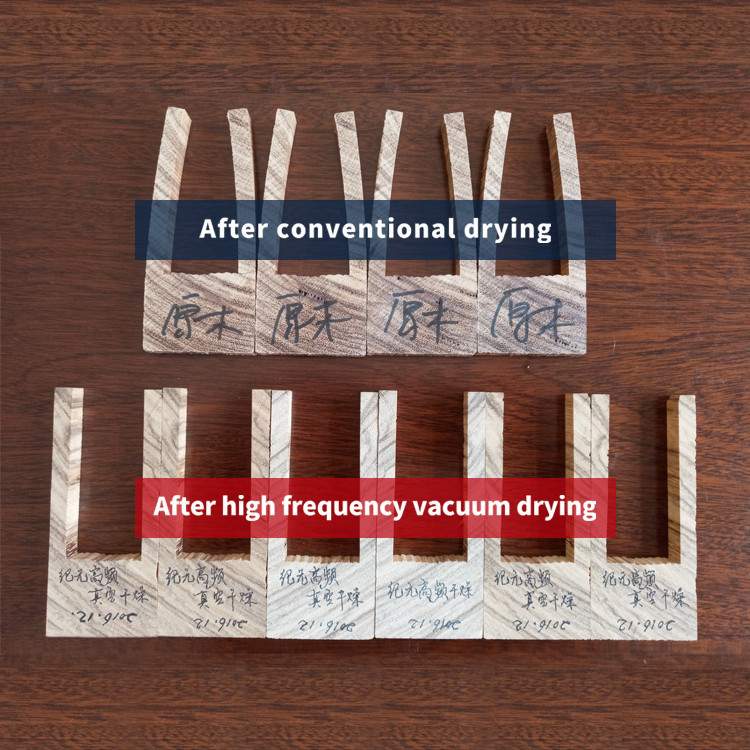

JYC’s system further enhances this process through vacuum conditions, lowering the boiling point of water and facilitating rapid moisture extraction without high surface temperatures. The result is a drastic reduction in drying time—up to 70% compared to conventional steam or hot air kilns—while minimizing case-hardening(unevenly dry), internal stresses, and dimensional instability.

Energy Efficiency and Environmental Leadership

The synergy between high frequency heating and vacuum technology yields exceptional energy utilization. By directly targeting water molecules, JYC’s system limits wasted energy typically associated with heating air or equipment structures. Operational energy consumption is reduced by as much as 50% compared to traditional dryers.

From an ecological standpoint, the closed-loop vacuum process eliminates volatile organic compound (VOC) emissions and prevents thermal degradation of wood polymers. There is no combustion or effluent output, aligning with stringent international environmental protocols and corporate sustainability goals.

Autonomous Operation and Process Control

JYC’s dryer incorporates programmable logic controllers (PLCs) and moisture content sensors to deliver full automation. The system self-regulates HF power output, vacuum pressure, and cycle duration based on real-time feedback, ensuring precision drying across wood species and initial moisture profiles.

Operators benefit from remote monitoring and diagnostic capabilities, reducing labor requirements and minimizing human error. This level of automation not only optimizes resource allocation but also enhances reproducibility and product quality.

Standard-Setting Authority in HF Wood Drying

JYC served as the drafting unit for China’s national standard for high frequency wood drying technology. Our equipment is the only system on the market that fully complies with these standards, which prescribe metrics for energy efficiency, drying uniformity, and product quality. This endorsement reflects JYC’s foundational role in advancing and legitimizing HF vacuum drying technology domestically and internationally.

Conclusion

JYC’s High Frequency Vacuum Wood Drying Machine represents the confluence of advanced applied physics, automation engineering, and ecological responsibility. It offers industrial users a definitive solution for high-speed, high-quality drying that reduces operating costs, meets environmental regulations, and operates with minimal supervision.

For enterprises committed to technological excellence and sustainable practice, JYC provides not just equipment, but an industry benchmark.

Other News

China's Heading Wood Drying Solution: The Standard Setting HF Vacuum Dryer from JYC

timer :

2025-08-26

Discover JYC High Frequency Woodworking Technology at Shanghai International Exhibition 2025

timer :

2025-08-19