BLOGS

Which is Better for Your Workshop?

When it comes to making wooden frames—whether for picture frames, cabinet doors, drawers, or wardrobes—choosing the right assembly method is crucial. Traditionally, wood frame clamps have been the go-to tool for craftsmen. However, with modern technology, high frequency (HF) frame assembly machines are becoming the preferred choice for woodworking factories and professional workshops. Let’s compare the two.

1. Efficiency

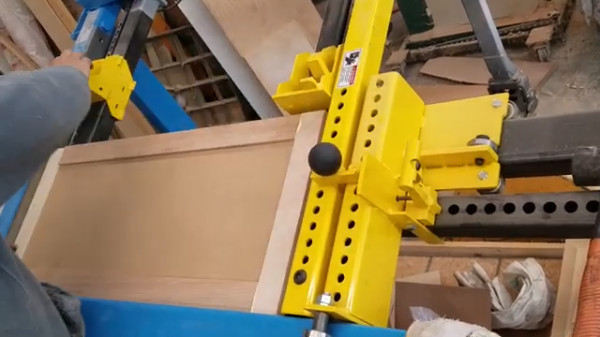

Wood Frame Clamps:

Clamps require manual setup, adjustment, and tightening. For each frame, the worker needs to carefully position the pieces, apply glue, and secure the clamp. This process can be slow, especially when producing frames in larger quantities.

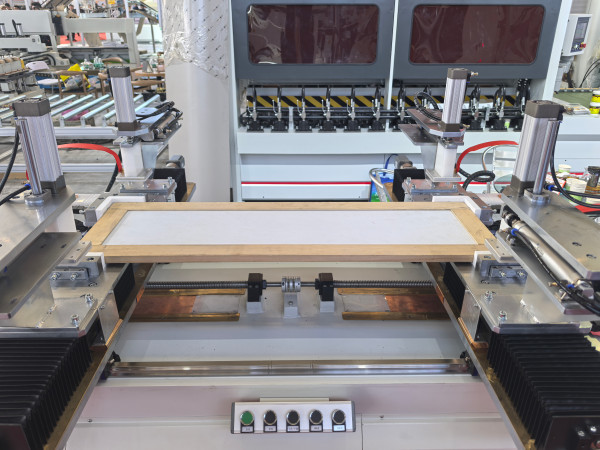

HF Frame Assembly Machines:

These machines use HF heating to cure glue within minutes. The assembly and pressing are automated, which means significantly faster production and consistent results. One machine can complete dozens of frames in the time it takes clamps to handle just a few.

2. Labor Requirement

Wood Frame Clamps:

Skilled workers must manually align and set up the frames, check squareness, and wait for the glue to dry. Each frame needs to be dealt with, which increases labor costs.

HF Frame Assembly Machines:

Once set up, the machine requires minimal manual handling. It eliminates the need for long clamping times and constant supervision, freeing workers to handle other tasks.

3. Bonding Quality

Wood Frame Clamps:

Bonding strength depends on how evenly the clamp applies pressure and how carefully the worker aligns the frame. Inconsistent pressure can lead to weak joints or visible gaps.

HF Frame Assembly Machines:

The machine applies uniform pressure and uses high frequency(RF) energy to heat the glue line internally, creating a stronger and more durable bond. The result is precise, tight joints with minimal risk of deformation.

4. Production Scale

Wood Frame Clamps:

Best suited for small workshops, DIY users, or custom one-off projects where speed is not a major concern.

HF Frame Assembly Machines:

Ideal for medium to large-scale production, where efficiency, consistency, and labor savings are essential. Factories producing cabinet doors, furniture frames, or decorative panels benefit the most.

While wood frame clamps remain useful for small-scale woodworking and hobbyists, they are limited in speed and consistency. For businesses aiming to achieve mass production, higher quality, and reduced labor costs, the high frequency frame assembly machine is the clear winner.

At JYC, we specialize in advanced high frequency woodworking machinery that helps manufacturers scale up their production with precision and efficiency. We also provide production line solutions to assist the enterprise in greatly increasing production and reducing costs.

Other News

JYC Enhances HF Joining Technology to Support Ultra-Thin 4mm Wood Panels

timer :

2025-10-14

Celebrating the Mid-Autumn Festival — JYC Shares Warmth and Appreciation

timer :

2025-10-06